At Quimipol, we know that true innovation starts with choosing the right materials. That’s why we want to take you on an exploratory journey into one of modern industry’s most versatile and sustainable treasures: Polypropylene (PP). This material is not just a component; it is a revolution that redefines the boundaries of what is possible in manufacturing and sustainability.

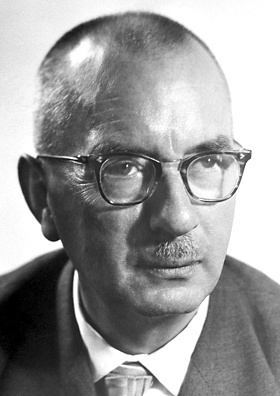

A Transforming Discovery

The polypropylene odyssey began in 1954, when scientists Giulio Natta and Karl Rehn succeeded in polymerising propylene in a laboratory, giving life to a new plastic material that would soon change the world. This discovery was so revolutionary that Natta was awarded the Nobel Prize in Chemistry in 1963, marking the beginning of the polypropylene era in global industry.

Since then, PP has become one of the world’s most widely produced and versatile plastics, with applications ranging from simple packaging to complex automotive components and advanced medical equipment. Its exponential growth is a testament to its unrivalled adaptability and efficiency.

Physical and Chemical Properties: The Secret to Your Success

Polypropylene is a semi-crystalline thermoplastic notable for its unique balance of properties.

– Strength and Durability: Polypropylene is an exceptionally resistant material to tensile, compression, impact and abrasion. Its resistance to stress and kinking makes it ideal for repeated bending without breaking, even under extreme conditions. This durability and flexibility make it the best choice for a wide range of applications, from packaging and textiles to automotive parts and industrial components. For example, polypropylene is used to make ropes and hoses that resist wear and abrasion, as well as hinges and housings that can withstand heavy use.

– Lightweight: With a density of only 0.905 g/cm³, polypropylene is one of the lightest plastics on the market, even lighter than water. This exceptional lightness makes it an ideal material for a wide range of applications, from packaging and textiles to automotive parts and industrial components. Its ease of handling reduces worker fatigue and speeds up production processes. In addition, its low weight reduces fuel consumption in transportation, which translates into less environmental impact.

– Chemical Resistance: Polypropylene is resistant to a wide range of chemicals, including acids, bases, solvents and alcohols. However, its resistance varies depending on the type of chemical to which it is exposed. In general, polypropylene is highly resistant to dilute acids and bases, as well as aliphatic solvents such as hexane and heptane. It is also resistant to alcohols such as ethanol and methanol. However, it is less resistant to some aromatic solvents such as benzene and toluene.

– Heat Resistance: Polypropylene has a melting temperature of approximately 160°C. However, its continuous service temperature is generally between 5°C and 100°C. This temperature can vary depending on the type of polypropylene, the additives used and the shape of the final product. Polypropylene is a relatively heat-resistant material and can be used in applications requiring moderate temperatures. However, it is not suitable for applications requiring exposure to extremely high temperatures for long periods of time.

– Insulating Properties: Polypropylene is an exceptional electrical insulator, with high resistivity and low dielectric permittivity. This makes it the ideal choice for cables, housings and electrical components where safety and efficiency are paramount. In addition, polypropylene is an excellent thermal insulator, which means it reduces heat transfer and keeps the temperature constant. This property makes it ideal for construction applications such as wall, roof and pipe insulation. Production Process

Polypropylene (PP) is not found in nature, but is made from propylene, a gas derived from petroleum or natural gas. The PP production process is a fascinating journey involving chemistry, technology and precision:

1. Production of propylene:

Oil or natural gas is refined into various products, including propylene. This gas is separated by fractionation processes.

2. Polymerisation:

Propylene is polymerised, i.e. propylene molecules are joined together to form long polypropylene chains. Different polymerisation methods are used to obtain PP with different properties.

3. Extrusion and processing:

Polypropylene is extruded into different forms, such as granules, fibres or sheets. These forms are transformed into a wide range of products using different processing techniques such as injection moulding, blow moulding, profile extrusion, etc.

Major polypropylene producers:

- – ExxonMobil

- – Dow Chemical

- – LyondellBasell

- – Sinopec

- – SABIC

Types of Polypropylene and their Uses

It is mainly divided into two types: homopolymer (PPH) and copolymer (PPC).

- Polypropylene Homopolymer (PPH):

- It is the purest type of PP, composed only of repeating units of propylene.

- It is characterized by high rigidity, tensile strength and hardness.

- It is less impact-resistant than PPC, especially at low temperatures.

- It is used in:

- Containers: bottles, caps, containers, films.

- Automotive industry: bumpers, instrument panels, vents.

- Pipes and fittings: pipes for drinking water, drains, pipes and fittings for transporting chemicals.

- Fibres and textiles: carpets, carpets, ropes, fabrics.

- Appliances: housings, internal components.

2. Polypropylene Copolymer (PPC):

- It is produced by the polymerization of propylene with another monomer, such as ethylene.

- It is characterized by its greater flexibility, impact resistance, and transparency than PPH.

- It is less rigid than PPH and may have a lower tensile strength.

- It is used in:

- Containers and packaging: flexible films, bags, food packaging.

- Automotive industry: interior parts, engine components.

- Textiles and fibers: clothing, diapers, personal hygiene items.

- Toys and stationery: balls, rulers, folders.

- Medical products: syringes, gowns, masks.

Other types of Polypropylene:

- PP-EL-S Polypropylene: PP-EL-S is a type of black homopolymer polypropylene with electrical conductivity and fire resistance. It is manufactured with the addition of conductive particles that derive electrical charge, making it ideal for applications where the dissipation of static electricity is crucial.

- PP-S Polypropylene: PP-S is a type of copolymer polypropylene with high transparency and impact resistance. It is manufactured with the addition of an ethylene-propylene copolymer (EPM) as a second monomer, which improves the flexibility and breaking strength of the material.Isotactic polypropylene: It is a type of PPH with a more regular crystalline structure, which gives it greater rigidity and tensile strength.

- Syndiotactic polypropylene: It is a type of PPH with a less regular crystal structure, which gives it greater flexibility and impact resistance.

- Block copolymer: It is a type of PPC with two or more blocks of different monomers, giving it a combination of properties of both.

Quimipol: An ally of polypropylene

At Quimipol, we are experts in the use of polypropylene. This material has become a fundamental element in the manufacture of our equipment, both in the field of industrial ventilation and in the manufacture of laboratory equipment and solutions for the chemical industry in general.

Our close relationship with polypropylene is based on:

Experience: Extensive knowledge of the material and its applications.

Technology: State-of-the-art equipment for processing.

Innovation: Development of customized solutions for each client.

Commitment: Quality, efficiency and sustainability in our products.

Throughout our history, we have developed a deep understanding of the properties and benefits of polypropylene. This experience has allowed us to become a benchmark in the manufacture of industrial ventilation equipment with this material.

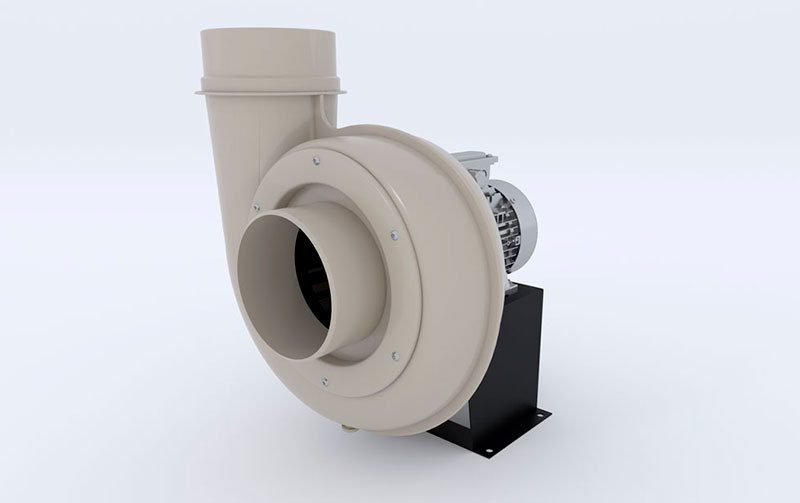

Quimipol’s ventilation equipment made of polypropylene offers a number of advantages:

Corrosion resistance: Ideal for humid and aggressive environments.

Lightweight: Facilitates installation and maintenance.

Durability: Long service life.

Recyclability: Contributes to sustainability.

At Quimipol, we are proud to be pioneers in the use of polypropylene in the ventilation industry. We are convinced that this material has great potential to continue driving innovation and the development of sustainable solutions for air management.

Some examples of Quimipol’s wide range of products made of polypropylene are:

Centrifugal fans: For the extraction of corrosive gases

Extraction and conveyance of gases: Installation of pipes for the chemical industry and laboratories

Gas purification: Manufacture of gas scrubbers and filters for the removal of pollutants.

Laboratory Equipment: Gas Cabinets, Cabinets and Laboratory Furniture customized for specific needs.

The future of polypropylene is bright, and at Quimipol we are ready to lead it.

Want to know more?

- Visit our website: https://quimipol.com

- Follow us on LinkedIn: https://es.linkedin.com/company/quimipolsl

- Contact Quimipol: https://quimipol.com/contacto/

Together we will build a more sustainable future with polypropylene!

If you want to read the full IT-AT-004 or download it, here is the link.