Plastic boilermaking

For the construction of industrial plastic products

Plastic boilermaking is a mechanical manufacturing speciality mainly related to the construction of plastic industrial products. It is based on plastic welding which is a combination of the techniques detailed below:

- Surface preparation: any impurities make welding difficult, so it is essential to thoroughly homogenise the surface to be welded.

- Warming: each plastic has a different glass transition temperature and it is only within this specific range that a perfect weld can be made.

- Consolidation: this is the gradual application of pressure to the specific section being welded, and which joins the two parts together.

- Cooling: this is the stage when the weld is cooled down, causing it to solidify once more.

We specialise in the manufacture and design of all types of equipment and parts in top quality thermoplastic materials. Thanks to our extensive experience in plastic boilermaking, we can offer you our own designs or adapt these to your needs.

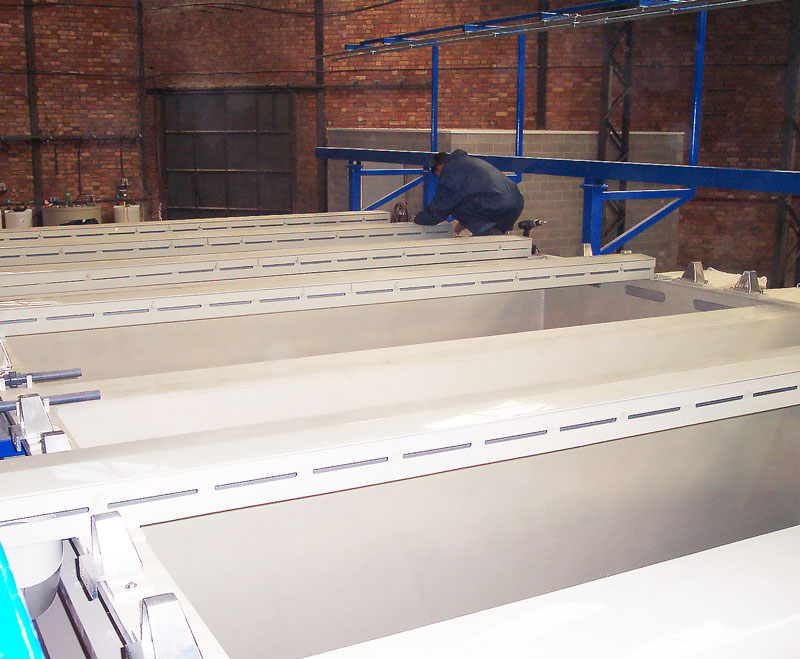

VATS

Made entirely of high quality, chemically resistant polypropylene (PPH). We have many different designs as well as personalised ones.

- Open or with a top cover

- Reinforcement wing

- Reinforcements with PPH-coated metal structure

- Flanged joints

- Inlets/Outlets

- Divisions

- Overflows

- Visual or electronic levels

- Ultrasounds

- Pumps

- Agitation systems

- Lagging

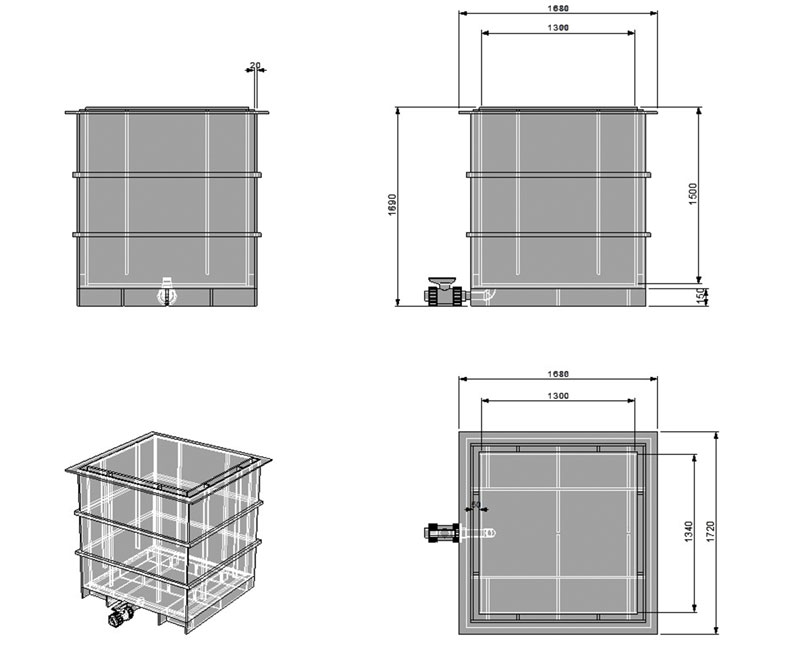

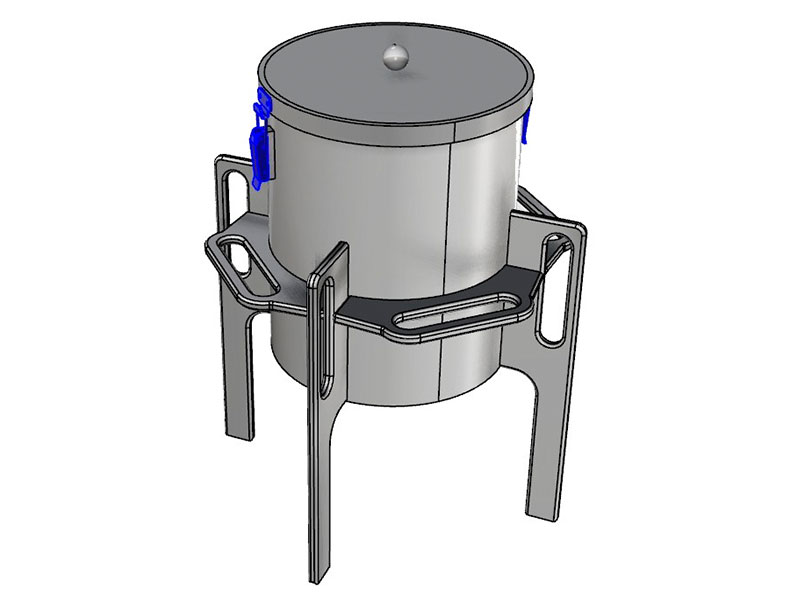

TANKS

Anti-corrosion tanks and vats made entirely of thermoplastic materials: PP, PVC, PVDF, and PE. These can be adapted to large capacities, dimensions, shapes and equipment. They are built according to recognised quality standards, using our proprietary boilermaking, continuous extrusion and polyfusion methods.

Advice and customised design, always selecting the materials that best suit the client’s specific needs. We have many different designs as well as personalised ones.

- Visual or electronic levels

- Manhole

- Lids

- Agitation systems

- Level switches

- Valves

- Registers

RECTANGULAR DUCTS

Production of rectangular ducts as an alternative to conventional PP or PVC pipes for gas/air extraction, adapted to the needs of each client.

- Straight sections

- Elbows

- Reductions

- Rectangular to round flanges