Dry gas treatment

The purpose of the filtration equipment is to control PM (sub-micron particulate matter). This is vitally important in the manufacturing process and to comply with the safety requirements established in the current regulations.

It functions by means of dry treatment, specifically adsorption, associated with deodorisation where the surfaces of our filters have sufficient reactivity efficiency to form chemical bonds with certain reactive gases, the adsorbates.

We have units capable of filtering volatile organic compounds, ammonia and amines, inorganic acids, chlorine, formaldehyde and alcohol.

Filter Holder

Retain gases or particles preventing these being released into the atmosphere

Filter holders are filtration devices used to retain gases or particles to prevent them being released into the atmosphere. These compact units are inserted into the extraction equipment and can be installed either indoors or outdoors.

The purpose of these devices is to protect people and the environment, and to comply with emissions directives such as those of the EEC. The filter holders are made of RAL-7032 polypropylene (working temperature up to 80ºC) or other plastic materials for special applications, such as PVC or PE.

All our filter holders are equipped with a pre-filter slot (larger particle filter) to extend the life of the filters.

| Reference | Description | L | W | H | Ø | No. filters |

| PFILTROPP | PP filter holder 250 m3/h | 550 | 414 | 414 | 75 / 90 | 1×250 ESP |

| PFILTROPP800 | PP filter holder 800 m3/h | 600 | 460 | 460 | 160 | 1×800 ESP |

| PFILTROPP1700 | PP filter holder 1,700 m3/h | 935 | 412 | 610 | 250 | 1×1700 |

| PFILTROPP2800 | PP filter holder 2,800 m3/h | 950 | 610 | 610 | 315 | 1×2800 |

| PFILTROPP3400 | PP filter holder 3,400 m3/h | 1000 | 710 | 610 | 355/ 400 | 1×3400 |

| PFILTROPP5100 | PP filter holder 5,100 m3/h | 1100 | 980 | 610 | 450 | 3×1700 |

| PFILTROPP6800 | PP filter holder 6,800 m3/h | 1435 | 1300 | 610 | 550 | 2×3400 |

| PFILTROPP8400 | PP filter holder 8,400 m3/h | 1510 | 1590 | 610 | 550 | 3×2800 |

| PFILTROPP10200 | PP filter holder 10,200 m3/h | 1560 | 1300 | 900 | 650 | 2×3400 + 2×1700 |

*Filter holders with different filtration stages available. Including combined filtration (Particulate/Carbon filters)

AP module filter holder

Units with maximum adsorption capacity

The filter holders for AP modules are high performance filtration devices used to retain highly concentrated corrosive gases at high concentrations, to prevent these being released into the atmosphere. These compact units are inserted into the extraction equipment and can be installed either indoors or outdoors.

The purpose of these devices is to protect the environment and to comply with emissions directives such as those of the EEC.

The filter holders are made of RAL-7032 polypropylene (working temperature up to 80ºC) or other plastic materials for special applications, such as PVC or PE.

All our filter holders are equipped with a pre-filter slot (larger particle filter) to extend the life of the filters.

Filters

Cardboard frame

| Reference | Description | Dimensions | ∆P Initial (Pa) | ∆P Final (Pa) |

| PREFIL250MPF | Synthetic pre-filter G3/4 250 m3/h Cardboard frame | 250x250x48 | 50/125 | 250 |

| PREFIL800MPF | Synthetic pre-filter G3/4 800 m3/h Cardboard frame | 340x340x48 | 50/125 | 250 |

| PREFIL1700MPF | Synthetic pre-filter G3/4 1700 m3/h Cardboard frame | 287x592x48 | 50/125 | 250 |

| PREFIL2800MPF | Synthetic pre-filter G3/4 2800 m3/h Cardboard frame | 490x592x48 | 50/125 | 250 |

| PREFIL3400MPF | Synthetic pre-filter G3/4 3400 m3/h Cardboard frame | 592x592x48 | 50/125 | 250 |

Galvanised frame

| Reference | Description | Dimensions | ∆P Initial (Pa) | ∆P Final (Pa) |

| PREFILG250MPF | Synthetic pre-filter G3/4 250 m3/h Galvanised frame | 250x250x48 | 50/125 | 250 |

| PREFILG800MPF | Synthetic pre-filter G3/4 800 m3/h Galvanised frame | 340x340x48 | 50/125 | 250 |

| PREFILG1700MPF | Synthetic pre-filter G3/4 1700 m3/h Galvanised frame | 287x592x48 | 50/125 | 250 |

| PREFILG2800MPF | Synthetic pre-filter G3/4 2800 m3/h Galvanised frame | 490x592x48 | 50/125 | 250 |

| PREFILG3400MPF | Synthetic pre-filter G3/4 3400 m3/h Galvanised frame | 592x592x48 | 50/125 | 250 |

HEPA Filters

Absolute filters for particle retention

Particle filters, also known as HEPA (High Efficiency Particulate Air) filters work by capturing solid particles in a mesh of randomly arranged fibres. This mesh is made of glass fibre with a diameter of 0.5 μm. The most important factors to consider in a HEPA filter are the diameter of the fibres, the thickness of the filter and the speed of the particles.

The particles stick to the fibres through one of the following mechanisms:

- Interception: Where particles in an air stream brush against a fibre and stick to it.

- Impact: Where large particles are not able to avoid the fibres while in the air stream and are forced to impact directly with one of them. This effect increases with decreased separation between the fibres and increased airflow velocity.

- Diffusion: Smaller particles, especially those smaller than 0.1 µm, collide with gas molecules. This impedes and slows down their passage through the filter. This behaviour is similar to Brownian motion and increases the probability of a particle being caught by one of the two previous mechanisms. It is the most prevalent when the air flow is slow.

Absolute filters with a polyhedral structure and a polystyrene frame. Continuous elastomer seal.

Classes from E10 to H13. MPPS efficiency 85% to 99.95%.

| Reference | Description | Dimensions | ∆P Initial (Pa) | ∆P Final (Pa) |

| PREFILG250MPF | Lamair 250x250x48 99.9995% MPPS P H14 | 250x250x48 | 130 | 400 |

| PREFILG800MPF | Lamair 340x340x48 99.9995% MPPS P H14 | 340x340x48 | 130 | 400 |

| PREFILG1700MPF | Poliair 592x592x292 99.95% MPPS 4V H13 | 592x287x292 | 280 | 450 |

| PREFILG2800MPF | Poliair 592x592x292 99.95% MPPS 4V H13 | 592x490x292 | 280 | 450 |

| PREFILG3400MPF | Poliair 592x592x292 99.95% MPPS 4V H13 | 592x592x292 | 280 | 450 |

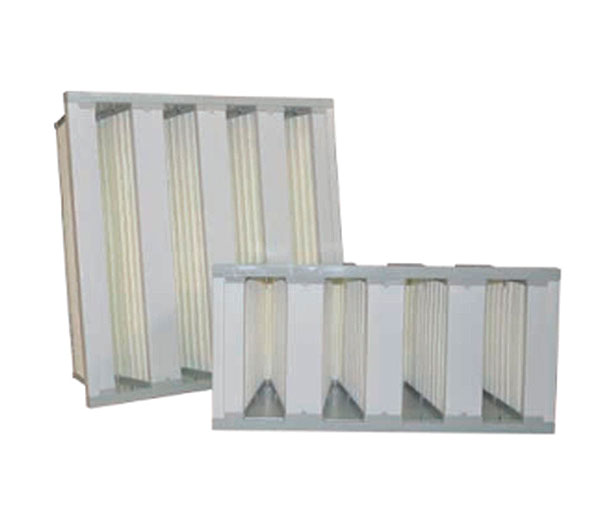

Activated carbon filters

High efficiency filtration and chemisorption

Activated carbon has a hexagonal crystalline structure, it is extremely porous and can reach surface areas in the order of 500 to 1500 square metres per gram of carbon. This surface area varies depending on the raw materials and the activation process.

To understand how activated carbon works, we must first analyse the process of adsorption, a phenomenon by which atoms on the surface of a solid attract and retain molecules of other compounds through Van der Waals forces. As this phenomenon occurs on the surface, the more surface area available, the better the adsorbency.

There are two types of adsorption phenomena:

- Physisorption: This is the most typical for activated carbon: this type of adsorption involves no electron exchange between the adsorbent and the adsorbate, making the process reversible.

- Chemisorption: This is less frequent: this type of adsorption is usually irreversible as modifications occur in the chemical structures of the adsorbate and the adsorbent.

With injected polystyrene structure.

Maximum temperature: 55º C

Maximum relative humidity: 60 %

Initial pressure loss at maximum flow rate: 120 Pa

Speed of passage: 0,5 m/s

8 distinct adsorbents are available for retaining different types of compounds.

T2 – Volatile Organic Compounds

| Reference | Description | Dimensions (mm) |

Design flow (m³/h) |

Maximum flow (m³/h) |

| FCA0250T2 | Activated carbon filter 250, VOCs | 250x250x50 | 110 | 180 |

| FCA0800T2 | Activated carbon filter 800, VOCs | 340x340x50 | 210 | 400 |

| FCA1700T2 | Activated carbon filter 1700, VOCs | 287x592x292 | 1250 | 1700 |

| FCA2800T2 | Activated carbon filter 2800, VOCs | 490x592x292 | 2000 | 2800 |

| FCA3400T2 | Activated carbon filter 3400, VOCs | 592x592x292 | 2500 | 3400 |

T4 – Ammonia and Amines

| Reference | Description | Dimensions (mm) |

Design flow (m³/h) |

Maximum flow (m³/h) |

| FCA0250T4 | Activated carbon filter 250, Ammonia / Amines | 250x250x50 | 110 | 180 |

| FCA0800T4 | Activated carbon filter 800, Ammonia / Amines | 340x340x50 | 210 | 400 |

| FCA1700T4 | Activated carbon filter 1700, Ammonia / Amines | 287x592x292 | 1250 | 1700 |

| FCA2800T4 | Activated carbon filter 2800, Ammonia / Amines | 490x592x292 | 2000 | 2800 |

| FCA3400T4 | Activated carbon filter 3400, Ammonia / Amines | 592x592x292 | 2500 | 3400 |

T5 – Inorganic Acids

| Reference | Description | Dimensions (mm) |

Design flow (m³/h) |

Maximum flow (m³/h) |

| FCA0250T5 | Activated carbon filter 250, Inorganic Acids | 250x250x50 | 110 | 180 |

| FCA0800T5 | Activated carbon filter 800, Inorganic Acids | 340x340x50 | 210 | 400 |

| FCA1700T5 | Activated carbon filter 1700, Inorganic Acids | 287x592x292 | 1250 | 1700 |

| FCA2800T5 | Activated carbon filter 2800, Inorganic Acids | 490x592x292 | 2000 | 2800 |

| FCA3400T5 | Activated carbon filter 3400, Inorganic Acids | 592x592x292 | 2500 | 3400 |

T6 – Chlorine

| Reference | Description | Dimensions (mm) |

Design flow (m³/h) |

Maximum flow (m³/h) |

| FCA0250T6 | Activated carbon filter 250, Chlorine | 250x250x50 | 110 | 180 |

| FCA0800T6 | Activated carbon filter 800, Chlorine | 340x340x50 | 210 | 400 |

| FCA1700T6 | Activated carbon filter 1700, Chlorine | 287x592x292 | 1250 | 1700 |

| FCA2800T6 | Activated carbon filter 2800, Chlorine | 490x592x292 | 2000 | 2800 |

| FCA3400T6 | Activated carbon filter 3400, Chlorine | 592x592x292 | 2500 | 3400 |

T7 – Formol and Formaldehyde

| Reference | Description | Dimensions (mm) |

Design flow (m³/h) |

Maximum flow (m³/h) |

| FCA0250T7 | Activated carbon filter 250, Formaldehyde | 250x250x50 | 110 | 180 |

| FCA0800T7 | Activated carbon filter 800, Formaldehyde | 340x340x50 | 210 | 400 |

| FCA1700T7 | Activated carbon filter 1700, Formaldehyde | 287x592x292 | 1250 | 1700 |

| FCA2800T7 | Activated carbon filter 2800, Formaldehyde | 490x592x292 | 2000 | 2800 |

| FCA3400T7 | Activated carbon filter 3400, Formaldehyde | 592x592x292 | 2500 | 3400 |

T8 – Odours and Alcohols

| Reference | Description | Dimensions (mm) |

Design flow (m³/h) |

Maximum flow (m³/h) |

| FCA0250T8 | Activated carbon filter 250, Odours and Alcohols | 250x250x50 | 110 | 180 |

| FCA0800T8 | Activated carbon filter 800, Odours and Alcohols | 340x340x50 | 210 | 400 |

| FCA1700T8 | Activated carbon filter 1700, Odours and Alcohols | 287x592x292 | 1250 | 1700 |

| FCA2800T8 | Activated carbon filter 2800, Odours and Alcohols | 490x592x292 | 2000 | 2800 |

| FCA3400T8 | Activated carbon filter 3400, Odours and Alcohols | 592x592x292 | 2500 | 3400 |

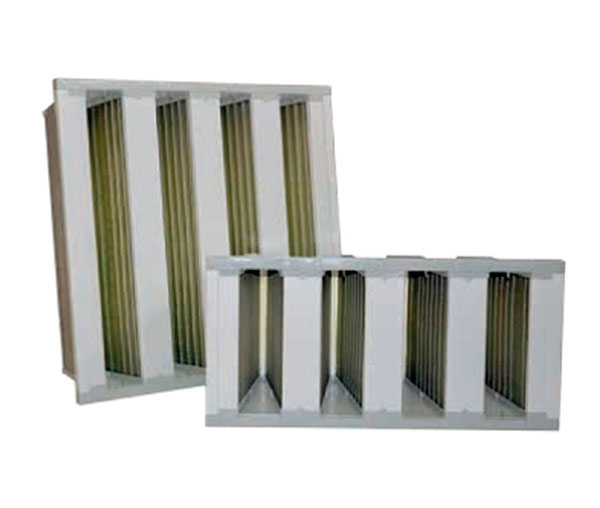

AP module activated carbon filters

Reusable filters with high adsorption capacity

AP modules are V-shaped plastic cassettes made of granular activated carbon. These filters are reusable thanks to a removable cover on the side, which means that the carbon can be replaced and the cassette can be reused. This type of chemical filter is characterised by a higher absorption capacity than other disposable filters. 76mm carbon bed in the passage section.

Complete AP-12 modules

| Reference | Description | Dimensions |

| FCAAP1215 | Cassettes AP12 ALPHASORB 15 | 299x295x299 |

| FCAAP128 | Cassettes AP12 ALPHASORB 8 | 299x295x299 |

| FCAAP128A | Cassettes AP12 ALPHABLEND 8A | 299x295x299 |

Granular activated carbon for refilling the AP modules.

| Reference | Description | Weight |

| CAALPHA15 | Sack of Carbon ALPHASORB 15 | 22.7 Kg |

| CAALPHA8 | Sack of Carbon ALPHASORB 8 | 22.7 Kg |

| CAALPHA8A | Sack of Carbon ALPHABLEND 8A | 18.5 Kg |

Alphasorb 15 → Caustic-impregnated activated alumina spheres for removing hydrogen sulphide (H2S), sulphur dioxide (SO2), chlorine gas (Cl2) and acidic gases in general.

Alphasorb 8 → Potassium permanganate-impregnated activated alumina spheres for removing formaldehyde, ethylene and oxidisable gases.

Alphablend 8A → Mixture of virgin activated carbon and potassium permanganate-impregnated activated alumina spheres, highly effective for a large number of gases and odours.

NOTE: Two cassettes contain approximately 2Kg of carbon.