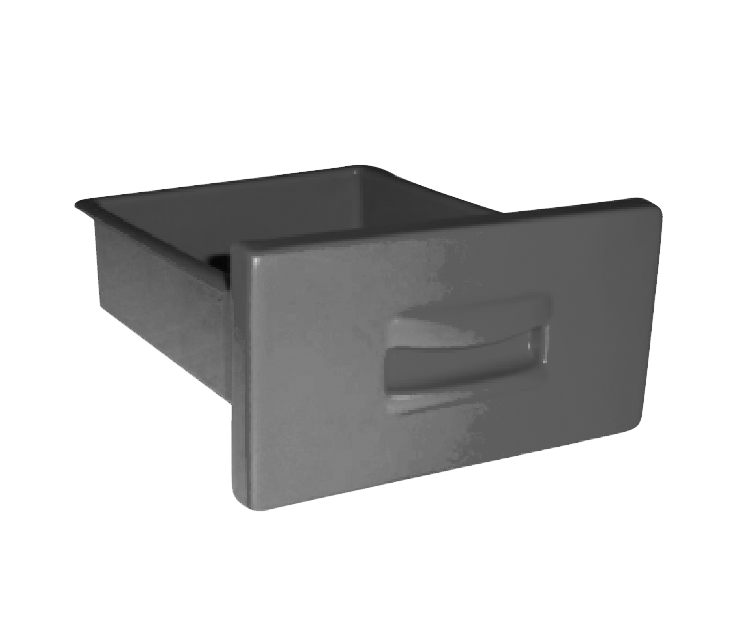

Thermoforming

Manufacture of large batches at competitive prices

We have a wide range of vacuum thermoforming machinery, ovens and presses to complete all stages of production:

- Mould and tool construction

- Prototype manufacturing

- Production of small batches

- Production of large batches

One of the main advantages of this system is the production of large batches at a reduced price compared to other production processes.

Materials:

- Polypropylene: PP-H, PP-EL, PP-EL-S

- Polyethylene: PE

- Polystyrene: PS

- Polyvinyl chloride: PVC

- Polyvinylidene fluoride PVDF

- Polyethylene terephthalate: PET

- Acrylonitrile butadiene styrene: ABS

- Polycarbonate: PC

- Polymethylmethacrylate: PMMA

- Phenolic resins

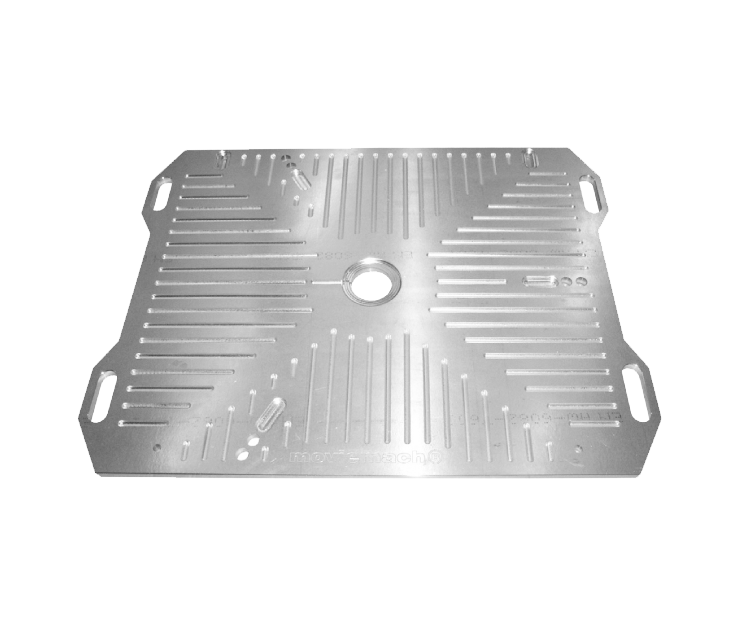

CNC Milling Machines

CNC milling machines for non-ferrous materials

The computer numerical control (CNC) is a system that enables the position of a physical element to be controlled at all times. This is achieved by using a program and a set of added commands. Through these two elements you can control the coordinates of a specific point (the tool working the product) with respect to the origin (the output position).

We must emphasise the importance of the CAM (computer aided manufacturing) program when the CNC program is difficult to write. In many cases, the CAM program works in conjunction with computer aided design (CAD). The CNC programmer specifies the machining operations to be performed and the CAM program automatically creates the CNC program.

Quimipol has two 5-axis CNC milling machines (BERMAQ CR and BERMAQ EURO-199) for 3D moulding and high-speed machining

Applications:

- Model industry

- Marine sector

- Aeronautics sector

- Furniture manufacturing

- Control tools

- Craftsmanship

- Wood modelling tasks

- SIEMENS machining system (Sinumerik 840 D)

Materials:

- Polypropylene: PP-H, PP-EL, PP-EL-S

- Polyethylene: PE

- Polystyrene: PS

- Polyvinyl chloride: PVC

- Polyvinylidene fluoride PVDF

- Polyethylene terephthalate: PET

- Acrylonitrile butadiene styrene: ABS

- Polycarbonate: PC

- Polymethylmethacrylate: PMMA

- Phenolic resins

- Aluminium

- Wood

Bermaq CR

Bermaq CR

Useful machining dimensions:

X axis: 3000 mm

Y axis: 1600 mm

Z axis: 600 mm

Milling motor:

Motor power: 7.9 kWb

Motor speed: 1000-24000 r.p.m.

Milling handle: 3-20 mm

Maximum controlled-axis speeds:

X axis: 60 m/min.

Y axis: 58 m/min.

Z axis: 25 m/min.

Bermaq Euro-199

Bermaq Euro-199

Useful machining dimensions:

X axis: 3100 mm

Y axis: 1500 mm

Z axis: 450 mm

Milling motor:

Motor power: 12 kW

Motor speed: 1000-24000 rpm

Milling handle: 3-25 mm

Maximum controlled-axis speeds:

X axis: 75 m/min.

Y axis: 65 m/min.

Z axis: 25 m/min.