Which Material to Choose According to Use

At Quimipol, we are manufacturers of polypropylene laboratory sinks. We help you choose the most suitable material based on three key criteria: chemical resistance, working temperature, and impact/shock strength.

Laboratory sinks can be made from different materials, but each one performs better in certain environments and applications. Below, we explain the advantages and limitations of the three most common: polypropylene (PP-H), stainless steel, and ceramic stoneware.

Polypropylene (PP-H) Sinks: Chemical Resistance and Minimal Maintenance

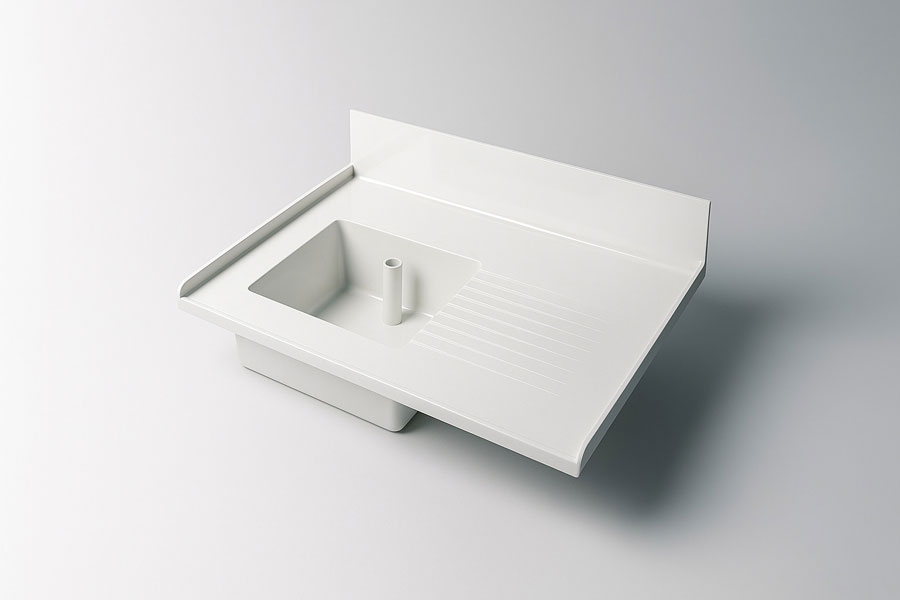

PP-H polypropylene sinks are Quimipol’s top recommendation for wet chemistry laboratories, educational settings, and quality control facilities.

Their excellent chemical resistance to acids, bases, and common solvents, combined with their minimal maintenance, make them a safe, durable, and practical choice.

In real projects, polypropylene has withstood prolonged exposure to 37% HCl —with subsequent cleaning and an intact surface— as well as brief contact with 96% H₂SO₄ without visible damage. This combination of reliability and easy cleaning makes PP-H the most balanced material for most laboratory sinks.

Main Advantages:

- High chemical compatibility with most acids and bases.

- Minimal maintenance: no pitting, no corrosion, easy to clean.

- Custom manufacturing available: bowls, drainboards, splash guards, and structural reinforcements.

- Long service life even in intensive-use laboratories.

Best Practices:

- Avoid sustained temperatures above 70–80 °C.

- Monitor the use of aromatic or chlorinated solvents during prolonged exposure.

- Use grids or protectors to absorb glass impacts or heavy loads.

At Quimipol, we manufacture custom polypropylene laboratory sinks, ensuring strength and maximum durability.

Stainless Steel Sinks (AISI 304/316): Mechanical Strength and Chemical Limitations

Stainless steel laboratory sinks stand out for their great mechanical strength and hygienic appearance, but they present important limitations against agents such as chlorides, HCl, or FeCl₃, which can cause pitting or localized corrosion even in 316 grades.

When to Choose Stainless Steel:

- Areas with high mechanical demand or frequent movement of metal utensils.

- Applications with strictly controlled chemical discharges and no chlorides.

Risks and Prevention:

- In the presence of salts or chlorinated acids, replace steel with Quimipol polypropylene sinks.

- Always dry the bowl after use and inspect the surface periodically.

- In mixed environments, combine stainless steel countertops with PP-H bowls to maximize durability.

Steel remains useful, but when chemical resistance is the priority, polypropylene laboratory sinks offer far superior performance.

Ceramic Stoneware Sinks: Thermal Stability vs. Fragility

Ceramic stoneware offers excellent chemical inertness and high thermal resistance, making it ideal for processes where temperature is the critical factor.

However, its fragility to impacts and the need for precise sealing limit its use in environments with heavy handling.

Advantages:

- High thermal tolerance (ideal for hot baths or long digestions).

- Very good chemical resistance to strong acids.

Limitations:

- Risk of chipping from impacts or concentrated loads.

- Requires professional installation with controlled joints and protective grids.

In many cases, Quimipol recommends replacing ceramic stoneware with reinforced polypropylene sinks, offering the same watertightness with greater mechanical strength.

Material Comparison Table

| Criterion | Polypropylene (PP-H) Sinks | Stainless Steel (304/316) | Ceramic Stoneware |

|---|---|---|---|

| Chemical resistance | Excellent | Medium (risk with chlorides/HCl) | Excellent |

| Thermal resistance | Good (≤ 80 °C) | Good | Very high |

| Impact resistance | Good (with grid) | Very good | Low |

| Maintenance | Very low | Medium | Medium-high |

| Overall durability | High | High (without chlorides) | High (low impact risk) |

Common Mistakes and Quimipol Solutions

- Installing stainless steel where chlorides or HCl are present

→ Solution: Quimipol polypropylene sinks, fully corrosion-resistant. - Pouring very hot baths directly into PP-H

→ Solution: Cool or dilute beforehand, or combine with heat-resistant countertops. - Installing ceramic stoneware without protection

→ Solution: Use protective grids.

Real Cases Observed by the Quimipol Technical Team

- Chemical digestions: polypropylene sinks maintained their surface intact after exposure to 37% HCl.

- Metal laboratories: stainless steel 316 developed pitting within 6 months; replacement with PP-H solved the issue.

- Quality control: ceramic stoneware sinks chipped; switching to reinforced PP-H eliminated breakages.

- University teaching: polypropylene sinks showed greater tolerance and easier cleaning.

Conclusions and Recommendations

- Wet chemistry or educational laboratories: Quimipol PP-H polypropylene sinks.

- Processes with metals or chlorides: avoid stainless steel; use PP-H or ceramic stoneware with protection.

- High recurring temperature: ceramic stoneware or PP-H with thermal protocol.

- Intensive use: PP-H for its low maintenance and excellent chemical resistance.

Quimipol Laboratory Sinks: Built to Last

At Quimipol, we are manufacturers of polypropylene laboratory sinks, fully custom-designed and manufactured.

Each sink leaving our workshop combines chemical resistance, durability, and technical precision to adapt perfectly to your process.

This article is directly related to:

|

Polypropylene Sink: The Ideal Solution for Demanding Laboratories |

Do you need technical advice or a custom quote?

Contact us and our team will provide the optimal solution:

Request your custom polypropylene laboratory sink at Quimipol

———————————–

About the Author

Sergi Vinuesa – Sales Manager at Quimipol