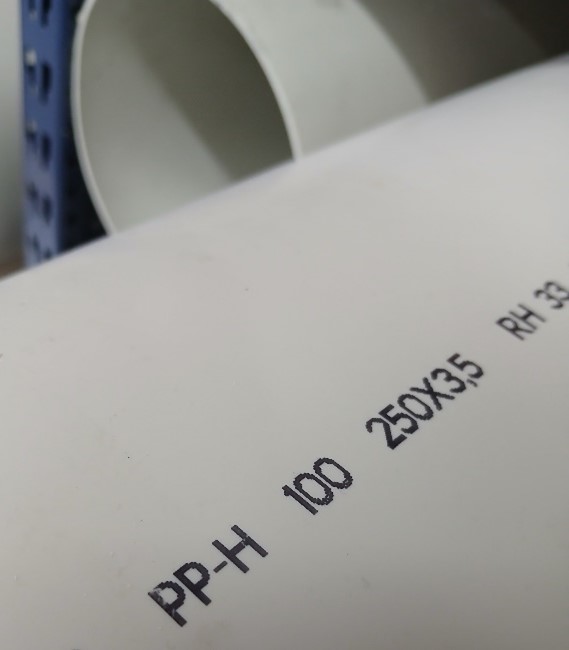

Polypropylene (PP-H) Ducting: The Safe and Effective Choice for Laboratory Facilities and the Chemical Industry

The safe handling of substances in laboratory environments and in the chemical industry depends not only on specialized procedures and equipment, but also on the materials with which the extraction systems are designed. In these environments, exposure to corrosive vapors and gases, such as those produced in laboratory fume cupboards, presents significant risks to both personnel and the work environment. Choosing a material that not only meets safety standards, but also offers durability and strength is critical, and in this area, homopolymer polypropylene (PP-H) ducting has positioned itself as the most effective and reliable solution.

Polypropylene Homopolymer (PP-H): Designed for Demanding Environments

PP-H is an enhanced, specialized type of polypropylene, with outstanding resistance to harsh chemicals, corrosion, and temperatures. Its ability to withstand the most extreme chemical challenges makes it a key component in applications where PVC, galvanized steel, or even stainless steel do not offer the same strength.

This type of polypropylene is ideal for extraction systems in laboratories and chemical production plants due to its ability to maintain structural integrity against highly corrosive compounds, thus protecting both the system and the work environment.

Material Comparison: PP-H, PVC, and Stainless Steel

To understand why homopolymer polypropylene (PP-H) is the most suitable choice in extraction systems, it is useful to compare it to other common materials such as PVC and stainless steel. The following table summarizes the main differences:

| Property | PP-H | PVC | Stainless Steel |

|---|---|---|---|

| Chemical resistance | Excellent | Good | Very good, but sensitive to concentrated acids and chlorides |

| Corrosion resistance | Excellent | Good | Limited to environments with strong chlorides or acids |

| Durability | Loud | Moderate | High, but requires maintenance to prevent corrosion |

| Weight | Light | Light | Heavy |

| Thermal adaptability | Up to 90°C | Limited (< 60°C) | Very high, suitable for high temperatures. |

| Initial cost | Moderate | Low | High |

| Maintenance | Minimal | Frequent | High due to regular cleanings and anti-corrosion treatments. |

| Recyclability | 100% recyclable | Partially recyclable | Recyclable, but with a higher environmental footprint in production |

Main Advantages of PP-H over Other Materials

-

Corrosion and Chemical Resistance

– Unlike galvanized steel or PVC, PP-H effectively resists prolonged contact with acids, bases, and other aggressive compounds. In laboratory environments where corrosive vapours are handled, PP-H ensures the safety of the extraction system, minimising the risk of leaks and potential contamination.

-

Long Durability and Minimal Maintenance

– PP-H’s resistance to corrosion means that ducts remain operational for much longer without the need for frequent replacements or high maintenance costs. This results in a profitable long-term investment and safe operation for the laboratory or industrial plant.

-

Adaptability in high temperatures

– Unlike PVC, which can weaken in heat, PP-H maintains its structure even at temperatures close to 90°C, making it a safe material for gas extraction systems operating in conditions of high thermal demand.

-

Lightness and Ease of Installation

– The lightness of PP-H facilitates the transport and assembly of ducts in complex installations, reducing installation times and associated costs. In addition, the PP-H ducts are joined by thermofusion with material input, achieving a robust and hermetic heat-welded joint. This welding method ensures high corrosion resistance and prevents leakage, which is especially valuable in areas that require a versatile and adaptable design for ventilation and extraction systems.

Key Applications in Laboratories and Industrial Environments

In research laboratories and chemical production plants, emission control and safety are of paramount importance. PP-H ducting allows extraction installations to be carried out in environments where corrosive vapours pose a constant risk. This solution ensures a safer working environment and lower maintenance costs.

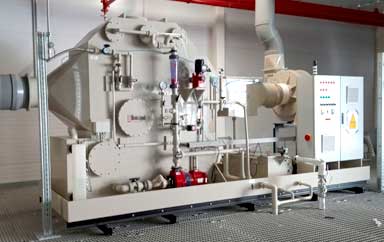

- Laboratory Extraction Systems: In research laboratories, where safety is paramount, PP-H ducts protect both personnel and the work environment. Gas extraction systems equipped with PP-H ducts are robust and stable, minimizing the risks associated with prolonged exposure to harsh chemicals.

- Chemical and Pharmaceutical Plants: In chemical and pharmaceutical production facilities, PP-H ducts are critical for the handling and extraction of hazardous compounds. Its ability to withstand products such as concentrated acids and bases allows the extraction system to maintain reliable and safe performance.

- Clean Rooms and Biotechnology: In areas where air quality is critical, PP-H contributes to maintaining controlled and safe environments, free of pollution. This makes it ideal in Cleanrooms for pharmaceutical manufacturing and biotechnology.

Polypropylene: An Investment in Safety and Sustainability

Economically, the initial cost of PP-H ducts is quickly amortized thanks to the durability and low maintenance of the material. Homopolymer polypropylene not only offers an extended lifespan compared to other materials, but, being a 100% recyclable material, it actively contributes to reducing the environmental impact of the industry. In a context where sustainability and resource efficiency are key, opting for PP-H is also an environmentally friendly decision.

Trust Quimipol for PP-H ventilation solutions tailored to your needs. Our team of experts will guide you through every step, from planning to installation. Ensure the safety and efficiency of your extraction system today!

Want to know more?

- Visit our website: https://quimipol.com

- Follow us on LinkedIn: https://es.linkedin.com/company/quimipolsl

- Contact us: https://quimipol.com/contacto/

———————————–

About the Author

Sergi Vinuesa – Sales Manager at Quimipol