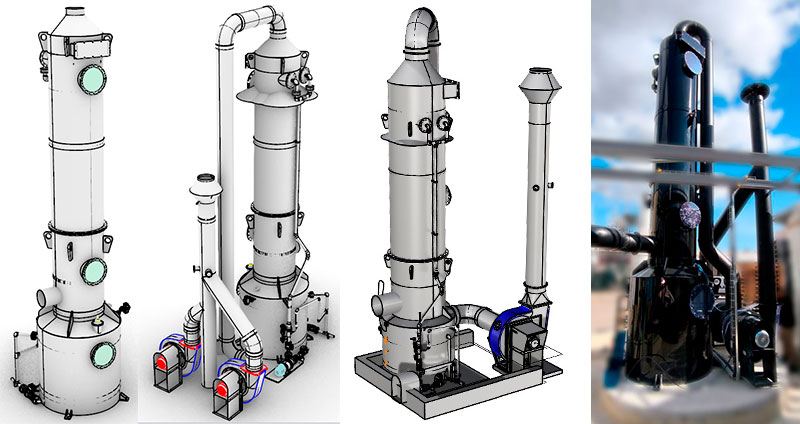

Anticorrosive Industrial Gas Scrubbers for Demanding Chemical Environments.

Robust, safe solutions designed to adapt to your project.

Reduce risks, improve efficiency, and ensure compliance with custom-made scrubbing systems.

We provide turnkey solutions for chemical and pharmaceutical environments where there’s no room for error.

Our gas scrubbers are designed to offer:

-

High chemical and mechanical resistance

-

Adaptability to ISO standards, ATEX Directives, Industrial Emissions Directives, and Machinery Directive (2006/42/EC)

-

Effective scrubbing of acidic compounds, alkaline gases, volatile organic compounds, and other specific gases

-

Low maintenance and easy cleaning

-

Compliance with emission limit regulations

Reliable solutions 100% tailored to your project. Save time and avoid surprises with systems designed to last.

Our Working Process

-

Analysis of your project and regulatory requirements

-

Custom design based on flow rates, gas type, and available space

-

In-house manufacturing with anti-corrosive materials (PP, PPEL-s, PVC, PVDF…)

-

On-time delivery and commissioning with technical support

-

Monitoring of operation and maintenance

Typical Applications

-

Chemical and petrochemical industry

-

Pharmaceutical and biotech industries

-

Waste and wastewater treatment

-

Metallurgical industry

-

Food and beverage industry

-

Semiconductors and battery manufacturing

Materials and Configurations

-

Bodies and structures: Polypropylene, electro-conductive polypropylene

-

Multi-stage scrubbing for higher efficiency

-

Option for integrated sensors, automation, and remote control

-

Adaptable to tight spaces and variable flow rates

-

Integration with complex systems including ATEX units

Confidence to Avoid Frustration

We understand your concerns:

-

That it complies with regulations

-

That it arrives on time

-

That it works the first time

-

That you can get in touch quickly if there’s an issue

Every system is designed specifically for your environment.

We don’t sell standard equipment.

We don’t sell standard equipment.