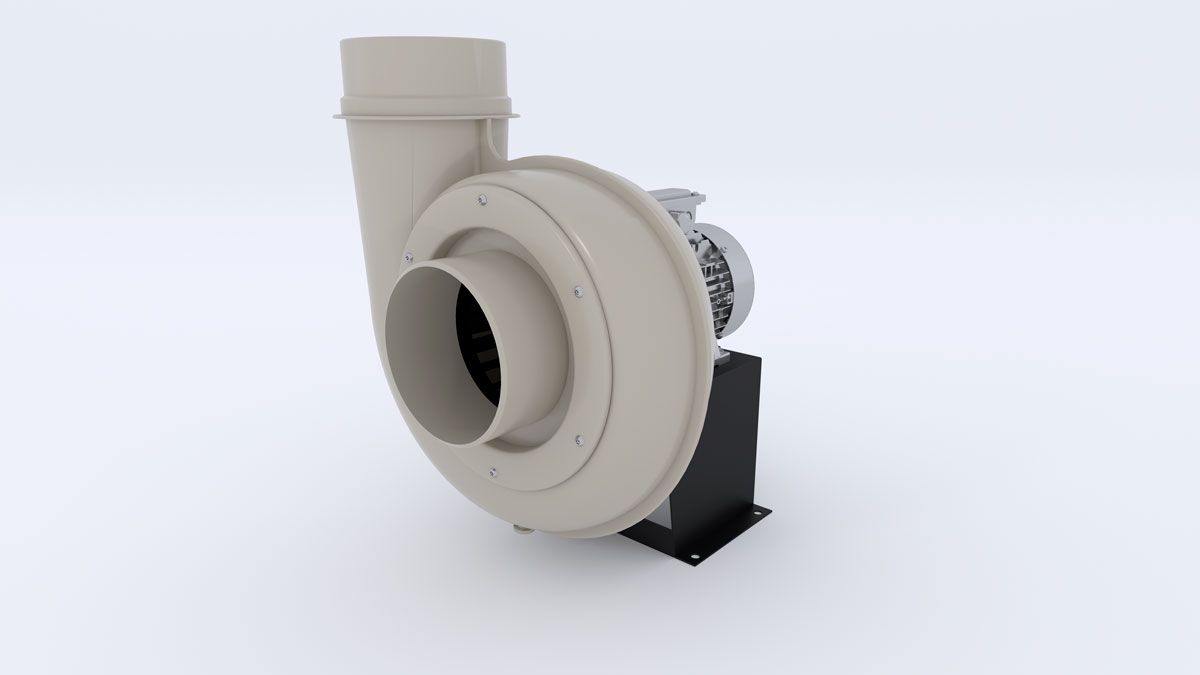

Quimipol centrifugal fans are an essential solution for various industries due to their ability to handle corrosive gases and other hazardous substances efficiently and safely.

With more than 60 years of experience in the market, Quimipol has perfected the technology and design of these fans, offering high quality products that meet the demanding needs of different sectors. Below, we explore the main industrial applications of Quimipol centrifugal fans and how they benefit each sector.

1. Chemical Industry

In the chemical industry, handling corrosive substances is a daily task. Quimipol centrifugal fans are specifically designed to resist the harmful effects of these gases, ensuring a safe and efficient working environment. These fans are used in air extraction systems to remove toxic and corrosive fumes, protecting both personnel and equipment from harm.

Benefits:

– Corrosion resistance: Manufactured from high strength materials, such as polypropylene, ensuring a long service life.

– Efficient fume extraction: Designed to handle large volumes of air, ensuring adequate ventilation.

– Regulatory compliance: Helps companies comply with environmental and safety regulations.

2. Pharmaceutical industry

The pharmaceutical industry requires rigorous control of air quality to avoid product contamination. Quimipol centrifugal fans are ideal for this sector, as they ensure a clean and contaminant-free environment. They are used in clean rooms and production areas.

Benefits:

– Contaminant control: Removes particles and vapours that could compromise the quality of pharmaceutical products.

– Sterile environment: Helps maintain sterile air conditions essential for drug production.

– Risk reduction: Minimises the risk of cross-contamination between different production batches.

3. Petrochemical industry

In the petrochemical industry, Quimipol centrifugal fans are essential for the extraction of hazardous gases and the ventilation of confined areas. These fans ensure the safe removal of flammable vapours and toxic gases, protecting both workers and facilities.

Benefits:

– Operational safety: reduce the risk of explosions and hazardous gas leaks.

– Hazardous gas handling: Capable of handling highly corrosive and toxic gases.

– Durability: Built to withstand extreme conditions and operate continuously.

4. Research Laboratories

Research laboratories, both in universities and private companies, use Quimipol centrifugal fans to maintain a safe and controlled environment. These fans are crucial in the extraction of vapours and gases generated during experiments and chemical processes.

Benefits:

– Safe environment: protect researchers from exposure to hazardous substances.

– Accuracy: They maintain a constant and controlled airflow, essential for accurate experiments.

– Versatility: They can be adapted to various laboratory configurations and specific needs.

5. Food Industry

In the food industry, ventilation is key to maintaining hygiene and product quality. Quimipol’s centrifugal fans help control and extract gases in processing and storage areas, preventing contamination and food spoilage.

Benefits:

– Air quality: maintain a clean environment, reducing the risk of contamination.

– Sanitary compliance: They comply with the safety and hygiene standards required in the food industry.

6. Water Treatment

In water treatment plants, Quimipol centrifugal fans are used to ventilate areas where chemicals and wastewater are handled. These fans ensure the elimination of odours and the extraction of corrosive gases, improving the working environment and treatment efficiency.

Benefits:

– Odour elimination: They improve working conditions by eliminating unpleasant odours.

– Corrosive gas handling: Ensure a safe environment by extracting toxic and corrosive gases.

– Operational efficiency: Contribute to more efficient operation of treatment plants.

7. Automotive Industry

In the automotive industry, Quimipol centrifugal fans are used in painting and coating processes, where it is crucial to control vapours and particles in the air. These fans ensure a clean and safe environment, improving the quality of finishes and protecting workers.

Benefits:

– Finish quality: They help remove particles that could affect the quality of the coating.

– Worker safety: They protect operators from exposure to toxic fumes.

– Environmental control: Maintain a controlled environment during painting processes.

8. Energy Production

In energy production plants, Quimipol centrifugal fans play a vital role in the ventilation of areas where hazardous gases are generated and handled. These fans ensure a constant airflow, improving the safety and efficiency of operations.

Benefits:

– Safety: They reduce the risk of accumulation of hazardous gases.

– Efficiency: Improve operational efficiency by maintaining a constant airflow.

– Reliability: Built to operate continuously in demanding environments.

Conclusion

Quimipol centrifugal fans are a versatile and efficient solution for a variety of industries, ensuring safety, efficiency and regulatory compliance. With more than 60 years of experience, Quimipol has established itself as a leading manufacturer of corrosion-resistant centrifugal fans, offering high quality products that adapt to the specific needs of each sector. If you are looking for a reliable and effective solution for ventilation and gas treatment in your industry, Quimipol is your best option.

Visit our range of:

Fans SERIES M PP Three-phase

———————————–

About the Author

Sergi Vinuesa – Sales Manager at Quimipol