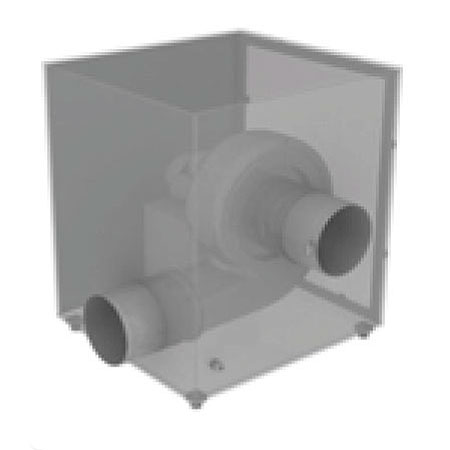

Fans with direct flange connection

Single-suction centrifugal fans, made of polypropylene (PP-H), highly resistant to chemical corrosion, used for extracting corrosive gases. Fans without motor support, supported via a PP flange at the inlet. Turbines with forward or backward blades depending on the model, directly coupled to the drive shaft, IP55 protection, Class F. Maximum working temperature recommended from -10ºC to +85ºC. Motors with IE2 efficiency up to 0.55kW. Premium models with IE3 efficiency.

*The ECODESIGN Directive 2009/125/EC does not apply to the range of anti-corrosion fans.

Motors:

– 2, 4 and 6 poles, according to versions.

– Standard supply voltage 230-400v 50Hz.

– Special windings for non-standard voltages, 50/60 Hz on request

– Single-phase models 230V-50Hz, on request.

– Motors with powers above 0.55kW energy efficiency IE3.

Fan accessories

Ventilation pipes and accessories

Table of power values

M SERIES PP STANDARD FLANGE

| Description | Turbine speed r.p.m. | Motor power kW | Max. flow rate (m³/h) | Max. pressure (mmca) | Sound pressure level (dB)* | Weight (Kg) | Max. intensity 400v (A) |

|---|---|---|---|---|---|---|---|

| Fan PP M-75 at 1500 rpm Flange | 1,400 | 0.06 | 110 | 6 | 62 | 4,0 | 0.25 |

| Fan PP M-75 at 3000 rpm Flange | 2,800 | 0.09 | 210 | 25 | 50 | 4,0 | 0.31 |

| Fan PP M-140 at 1500 rpm Flange | 1,400 | 0.06 | 400 | 35 | 50 | 6,0 | 0.37 |

| Fan PP M-140 at 3000 rpm Flange | 2,800 | 0.09 | 580 | 52 | 72 | 6,0 | 0.31 |

| Fan PP M-160 at 1500 rpm Flange | 1,400 | 0.25 | 775 | 20 | 68 | 11,0 | 0.76 |

| Fan PP M-160 at 3000 rpm Flange | 2,800 | 0.37 | 1,000 | 87 | 81 | 11,0 | 0.95 |

| Fan PP M-160 at 3000 rpm Plus Flange | 2,800 | 0.75 | 1,690 | 87 | 86 | 11,0 | 1.7 |

| Fan PP M-200 at 1000 rpm Flange | 950 | 0.25 | 1,500 | 15 | 54 | 11,0 | 0.79 |

| Fan PP M-200 at 1500 rpm Flange | 1,400 | 0.37 | 2,200 | 38 | 70 | 11,0 | 0.96 |

| Fan PP M-200 at 3000 rpm Flange | 2,800 | 1.5 | 2,400 | 155 | 81 | 24,5 | 2.9 |

| Fan PP M-200 at 3000 rpm Plus Flange | 2,800 | 2.2 | 3,300 | 155 | 90 | 24,5 | 4.4 |

| Fan PP M-200VG at 1000 rpm Flange | 950 | 0.37 | 1,580 | 35 | 62 | 22,0 | 1.07 |

| Fan PP M-200VG at 1500 rpm Flange | 1,400 | 0.55 | 2,400 | 73 | 77 | 22,0 | 1.41 |

*Sound pressure with free output at 1.5m.