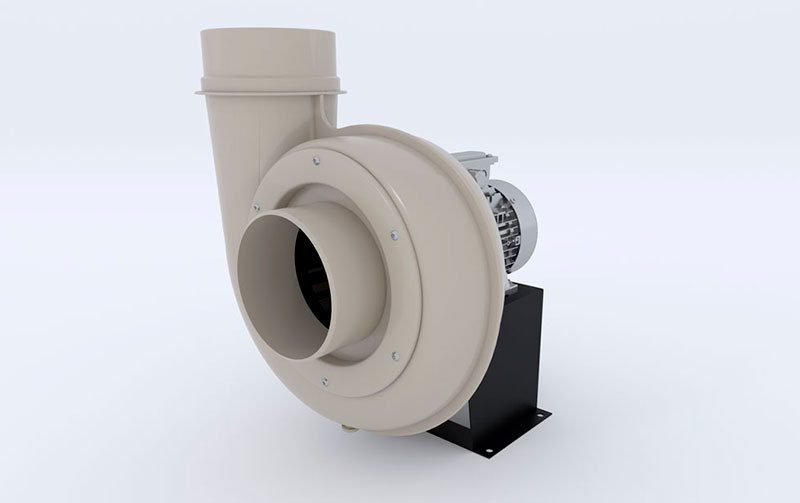

At Quimipol we not only design and manufacture anti-corrosive centrifugal fans.

We also test them in extreme conditions, in a controlled and safe way.

We have recently carried out a breakage test on one of our equipment. The objective was clear:

To identify its structural and functional limits, analyze its behavior in critical situations and apply real improvements to the design.

What is a burst test on industrial fans?

A crash test consists of bringing a fan to total failure under extreme conditions, to study its behavior in critical situations, this type of test allows:

- Verify the mechanical and structural strength of the assembly.

- Identify weak points in turbine, shaft, housing or fasteners.

- Validate the choice of anti-corrosion materials such as PP-EL, PVDF or stainless steel.

- Simulate real-world situations of extreme use: overpressure, foreign objects, vibration, clogging or mechanical fatigue.

- Apply tangible improvements in design, manufacturing, and assembly.

These tests are part of our culture of continuous improvement and reflect our commitment to the safety, reliability and real quality of our equipment.

How we did it

The trial was conducted in our test cage, a controlled and safe environment. The procedure was as follows:

- Operation at maximum speed and flow rate: the fan worked for several hours in forced conditions, monitoring temperature, vibration and consumption.

- Progressive loading: we increase the resistance of the system to force the stress on the turbine.

- Foreign body simulation: We introduced solid particles (metals, debris) that could be found in real industrial environments.

- Induced failure: Finally, the fan collapsed. The turbine fractured and the equipment stopped.

Far from seeing it as a mistake, that moment is the one that teaches us the most.

Results and improvements applied

After the post-break analysis, several improvements were implemented, already applied in new designs:

- Reinforcement of the turbine with new welding points to better absorb impacts.

- New shaft anchoring system, more stable and resistant to vibration.

- Optimization of dynamic balancing, to reduce mechanical stress in extreme conditions

These improvements are the result of real tests, with real data, in environments that simulate the worst possible scenario.

Why do we do it?

In many industrial sectors, fans work under demanding conditions: corrosive environments, the presence of flammable particles or gases. And at Quimipol we believe that manufacturing reliable ventilators is not only about designing them well, it is about testing them and checking that they comply.

Rehearsing until failure allows us to:

- Ensure that equipment meets (and exceeds) actual working conditions.

- Detect and correct weaknesses before they become breakdowns.

- Apply improvements that increase fan life and reduce maintenance costs.

Fans that work

At Quimipol, we have been designing and manufacturing anti-corrosion centrifugal fans in materials such as PP, PVC or PP-EL-S for years, designed for industrial environments where there is no margin for error.

And yes, over the years we have made many. We have tested them, we have installed them, we have put them to work… And we have also pushed them to the limit. Because when it is really manufactured, from time to time, some of it breaks. Sometimes because of a defect, sometimes because of incorrect use, and sometimes simply because it is part of the process of learning and improving.

The important thing is what you do with what you learn. And we are clear: Every controlled failure is an opportunity to improve.

As manufacturers, we have a responsibility to make sure that every fan that comes out of our hands is stronger, safer, and more reliable than the last.

Do you need a really sturdy fan?

If you are looking for a centrifugal fan that will operate safely, stably and durably even under demanding conditions, please contact us. We manufacture anti-corrosion centrifugal fans, with the experience and knowledge that you only get when you try, break and build back better.

Contact us here for more information

———————————–

About the Author

Sergi Vinuesa – Sales Manager at Quimipol