Centrifugal fans are fundamental elements in many industries, used for air extraction, ventilation and gas management.

To ensure their optimal operation and prolong their service life, it is crucial to implement a proper preventive maintenance plan. In this article, we will explore tips and best practices for centrifugal fan maintenance, highlighting the importance of each step and offering practical recommendations.

Detailed Inspection: Ensure the efficient operation of your centrifugal fan with regular inspections.

What is Preventive Maintenance?

Preventive maintenance refers to planned actions that are carried out on a regular basis to avoid unforeseen failures and to keep equipment in optimal working condition. In the case of centrifugal fans, proper maintenance not only ensures their performance, but also contributes to the safety of the working environment and compliance with regulations.

Importance of Preventive Maintenance

- Performance Optimisation: A well-maintained centrifugal fan runs more efficiently, which results in lower energy consumption and higher air extraction.

- Prolonged Lifetime: Regular maintenance interventions help prevent premature wear of critical components, which extends the lifetime of the equipment.

- Cost Reduction: Avoiding major repairs and early replacements saves costs in the long run and minimises unplanned downtime.

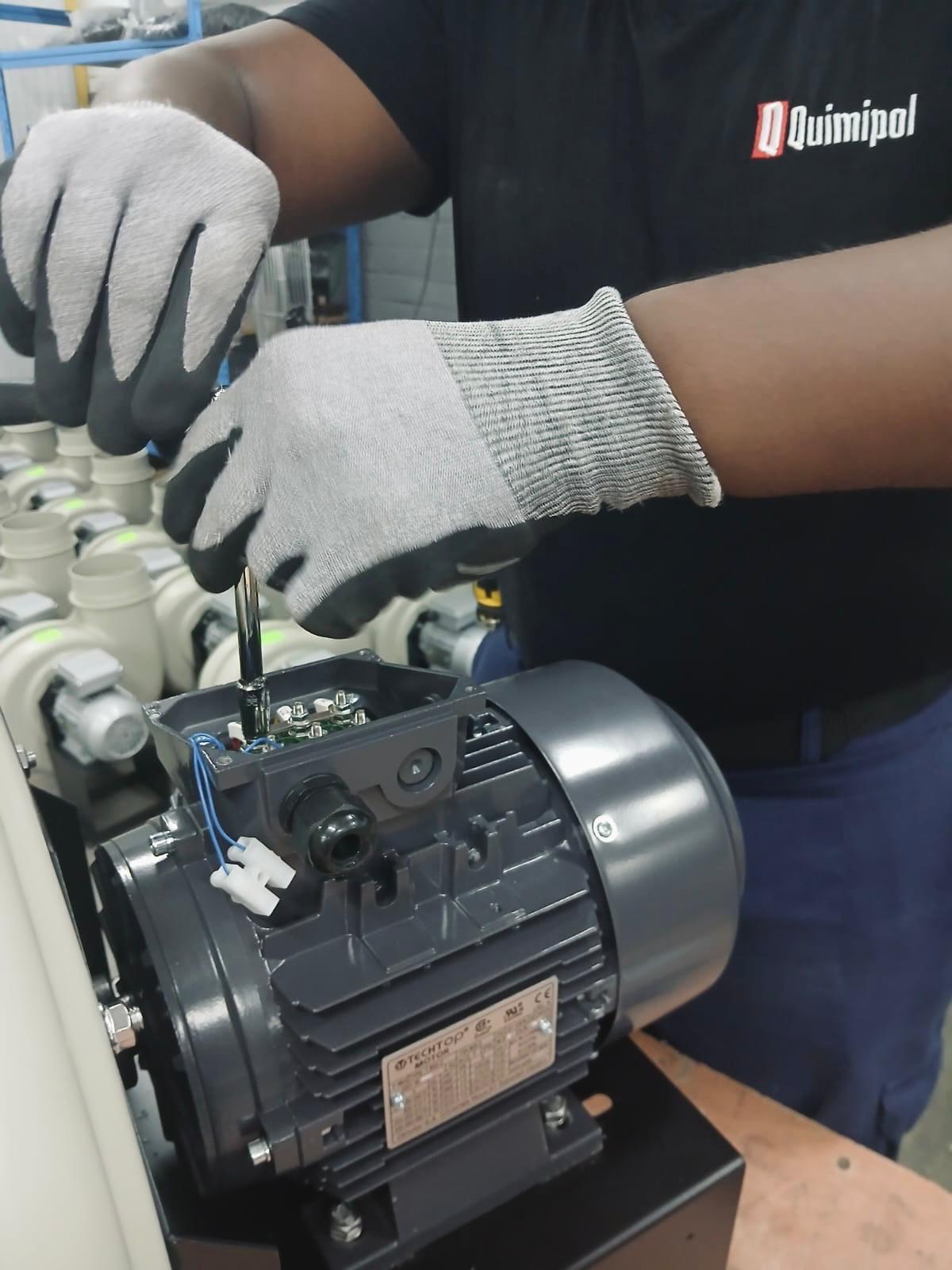

Worker cleaning and lubricating a centrifugal fan as part of preventive maintenance to optimize its performance.

Preventive Maintenance Tips

- Regular Inspection: Perform periodic visual inspections for signs of wear, dirt accumulation or corrosion on the exterior and interior parts of the fan.

- Component Cleaning: Regularly clean the impeller and the inside of the casing to ensure proper airflow and to avoid obstructions that may reduce efficiency.

- Checking Belt Tension: If the fan uses belts for power transmission, check and adjust the tension on a regular basis to avoid slippage and premature wear.

- Bearing Lubrication: Apply lubricant to bearings according to manufacturer’s specifications to reduce friction and prolong the life of moving components.

- Operational Testing: Conduct periodic tests to ensure that the fan operates within normal parameters of speed, temperature, noise and vibration.

- Energy Efficiency Evaluation: Optimise the performance of your fan with a variable frequency drive. These devices allow you to adjust the fan speed according to the needs of the moment, which reduces energy consumption and lowers operating costs. Variable frequency drives are especially useful in applications where ventilation demands vary, allowing for more precise and efficient control of airflow.

Best Practices

– Detailed Documentation: Maintain accurate maintenance records, including dates of service, interventions performed and relevant observations.

– Regular Scheduling: Establish a preventive maintenance schedule based on manufacturer’s recommendations and operating conditions.

– Staff Training: Ensure that operators and technicians are trained to perform basic maintenance and recognise signs of potential problems.

Life of Centrifugal Fans

The life of a centrifugal fan can vary significantly depending on several factors, including the quality of the equipment, operating conditions and regularity of maintenance. In general, it is estimated that a well-maintained centrifugal fan can have a service life of between 10 and 20 years. In terms of operating hours, a centrifugal fan can last between 20,000 and 40,000 hours of continuous operation. However, these figures can be increased if rigorous preventive maintenance practices are carried out and high quality components are used.

Component verification: Detect wear or damage on your centrifugal fan with regular inspections.

Conclusion

Preventive maintenance of centrifugal fans is a fundamental practice to ensure operational efficiency, prolong equipment life and minimise operating costs. At Quimipol, we are committed to providing not only high quality products, such as our corrosion resistant centrifugal fans, but also the knowledge and advice necessary to maximise the performance and durability of our equipment.

Implementing a proper preventive maintenance plan not only protects your equipment investment, but also enhances safety and efficiency in the workplace. Contact Quimipol today to find out how we can help you optimise the performance of your centrifugal fans and ensure a safe and productive working environment.

Visit our services of Installations / Maintenance

Visit our range of Centrifugal Fans

Contact us

———————————–

About the Author

Sergi Vinuesa – Sales Manager at Quimipol